Why OEM Piston Crowns Are Essential for Long-Term Engine Reliability

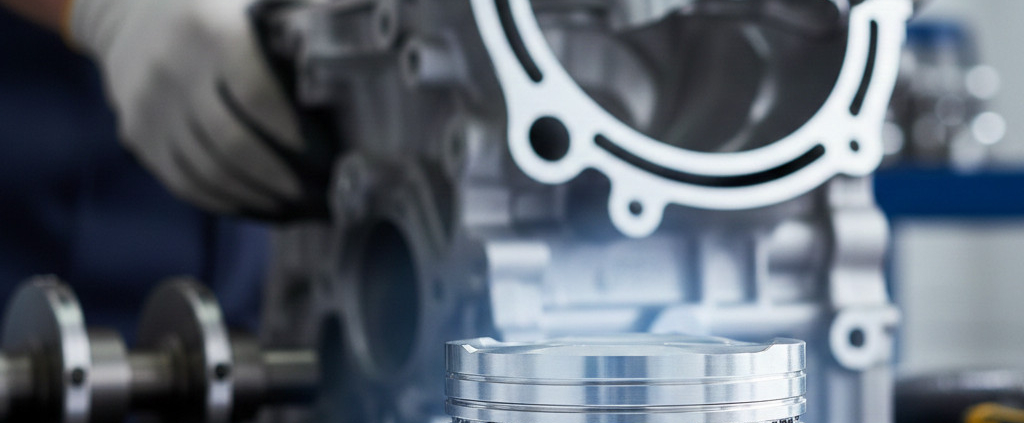

When it comes to marine engines, every component plays a critical role in maintaining efficiency, performance, and long-term durability. Among these components, the piston crown stands out as one of the most vital. As the top surface of the piston, the piston crown directly faces extreme combustion temperatures, intense pressures, and continuous mechanical stress. For these demanding conditions, choosing OEM piston crowns is not just a preference—it is a necessity for ensuring long-term engine reliability.

What Is an OEM Piston Crown?

An OEM (Original Equipment Manufacturer) piston crown is a genuine part produced by the same manufacturer that designed and built the engine. Unlike aftermarket copies, OEM piston crowns are engineered to meet the exact specifications, materials, and performance standards of the original engine design.

This ensures:

- Precise fit

- Accurate tolerances

- Maximum structural strength

- Consistent combustion efficiency

Why OEM Piston Crowns Matter for Marine Engine Reliability

1. Engineered for Extreme Conditions

Marine engines operate under harsh and highly demanding environments. The piston crown must withstand:

- Combustion temperatures exceeding 500°C

- High-pressure gas forces

- Thermal expansion and contraction cycles

- Carbon formation and residue buildup

OEM piston crowns are designed with tested metallurgy and heat resistance properties to handle these extreme factors without premature wear.

2. Perfect Compatibility With Engine Components

Compatibility issues with non-OEM parts can lead to:

- Improper sealing

- Increased friction

- Abnormal combustion

- Accelerated wear of pistons, liners, and rings

OEM piston crowns ensure seamless integration with the engine’s original design, maintaining correct clearances and performance parameters.

3. Guaranteed Material Quality

Leading engine manufacturers use high-grade alloys and casting processes to produce piston crowns. These materials are selected based on:

- Strength

- Thermal conductivity

- Resistance to corrosion

- Fatigue life

Aftermarket piston crowns often compromise on material quality to reduce manufacturing costs, which can significantly shorten engine lifespan.

4. Enhanced Combustion Efficiency

The geometry of the piston crown directly affects:

- Air–fuel mixing

- Ignition timing

- Thermal distribution

- Overall combustion stability

OEM crowns maintain the intended combustion bowl design, ensuring optimal fuel burn and reduced carbon deposits—both of which contribute to long-term engine performance.

5. Lower Risk of Engine Failures

Using non-standard or low-quality piston crowns increases the chances of:

- Cracking

- Thermal deformation

- Piston seizure

- Scuffing or scoring of liners

OEM components minimize these risks and reduce the chances of costly breakdowns, emergency repairs, or unplanned vessel downtime.

OEM Piston Crowns and Long-Term Cost Savings

Although OEM piston crowns may cost more upfront, they provide significant long-term savings by:

- Extending engine life

- Increasing fuel efficiency

- Reducing maintenance frequency

- Minimizing the risk of catastrophic failures

For ship operators, this reliability is essential for maintaining smooth operations and preventing delays in marine transportation schedules.

Why Choose a Certified Marine Parts Supplier?

A reliable marine parts supplier—such as RMS Marine Service—ensures that you receive:

- Genuine OEM piston crowns

- Verified quality documentation

- Global delivery support

- Expert technical guidance

By sourcing from certified suppliers, operators safeguard their engines from counterfeit or substandard components.

Conclusion

The piston crown is a crucial component in marine diesel engines, and its reliability directly influences the engine’s performance, efficiency, and lifespan. Choosing OEM piston crowns ensures superior durability, excellent combustion characteristics, and long-term engine protection. For fleet operators looking to minimize maintenance costs and maximize operational efficiency, OEM parts are the most dependable choice.

If you’re ready to source genuine, high-quality piston crowns, partnering with a trusted marine supplier is the first step toward securing long-term engine reliability.

Leave a Reply

Want to join the discussion?Feel free to contribute!