Understanding Flow Drill Technology: Precision, Efficiency & Industrial Applications

Flow drill, also known as thermal drilling or flow drilling, is an advanced, chipless method of creating holes in thin metal materials without the need for tapping or welding. The process uses heat and pressure to displace material and form a bushing, which is ideal for thread forming or structural strength in metalworking applications. This technique is highly efficient, precise, and cost-effective — making it popular in various industries like automotive, aerospace, manufacturing, and fabrication.

How Does Flow Drilling Work?

Flow drilling involves a specially designed conical drill bit made from solid carbide or tungsten. When the rotating bit is applied to a metal surface, frictional heat softens the material. Instead of removing the material, the tool pushes it downward and forms a collar or boss around the hole. This displaced material increases the thickness of the hole, allowing for stronger threads and a more secure hold for fasteners.

Key Advantages of Flow Drill Technology

- No Material Waste: As it’s a chinless process, there’s minimal waste generation, making it environmentally friendly.

- Increased Strength: The formed collar reinforces the hole, allowing threads to hold stronger even in thin materials.

- Time & Cost Efficient: Flow drilling eliminates secondary operations like welding nuts or using inserts, reducing production time and cost.

- Versatile: It can be used on a variety of materials including steel, stainless steel, aluminum, copper, and brass.

Applications of Flow Drill Technology

Flow drill technology is ideal for:

- Automotive chassis and frame construction

- HVAC duct systems

- Electrical enclosures and switchgear components

- Furniture assembly

- Renewable energy systems, such as solar panel mounts

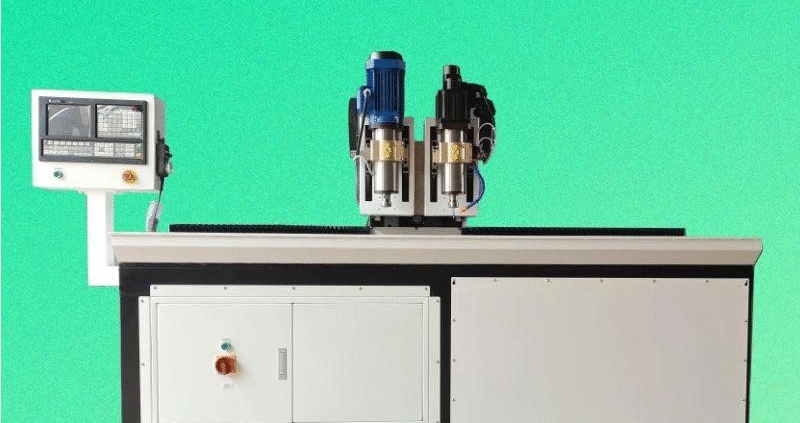

ZFDrill: Your Flow Drill Solution Partner

At ZFDrill, we specialize in high-performance flow drill tools engineered for precision and durability. Our thermal drilling systems are trusted across industries for their ability to deliver robust, clean, and reliable results. Whether you’re enhancing your production line or adopting lean manufacturing methods, ZFDrill’s thermal drilling solutions offer unmatched value.

Why Choose ZFDrill?

- Advanced CNC machining and quality control

- Custom flow drill tool designs based on your application

- Expert technical support and consultation

- Competitive pricing and global shipping

Conclusion

Flow drill technology is revolutionizing the way industries approach metal joining and threading. By leveraging this clean and efficient method, manufacturers can enhance product strength, reduce waste, and lower costs. If you’re looking to optimize your production with cutting-edge flow drilling solutions, trust ZFDrill for innovative tools and expert support.

Service hotline

+8618083708919

https://www.zfdrill.com/newsinfo/10.html

Sales Service Center

Xiaobei Third Group, Madian Xiaomazhuang Village, Binjiang Town, Taixing City

Leave a Reply

Want to join the discussion?Feel free to contribute!