The Value of CNC Precision Turned Components in Defense and Medical Applications

In an age wherein technology underpins nearly every factor of enterprise, few sectors call for the extent of accuracy, reliability, and repeatability required via the usage of the defense and clinical fields. At the coronary coronary heart of this precision lies a essential manufacturing method: CNC precision turning. The manufacturing of cnc precision turned components have become additives has become a cornerstone of innovation and functionality, empowering undertaking-vital applications ranging from battlefield device to lifestyles-saving scientific devices.

Understanding CNC Precision Turned Components

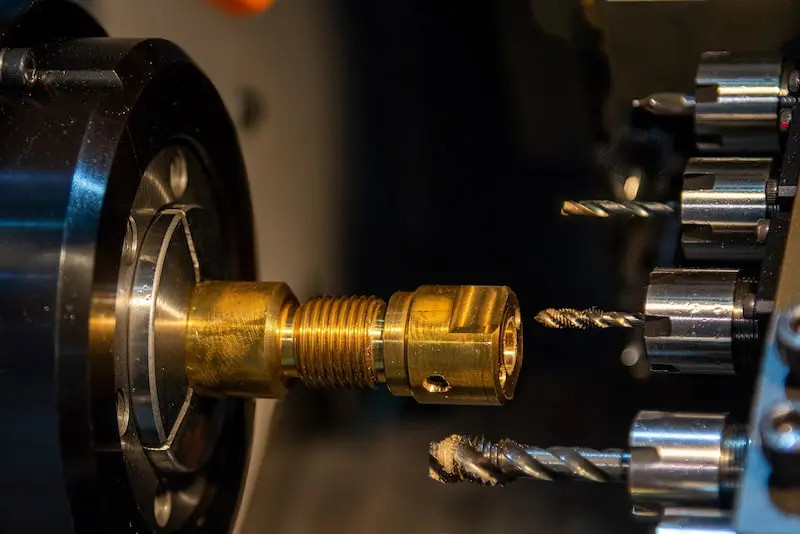

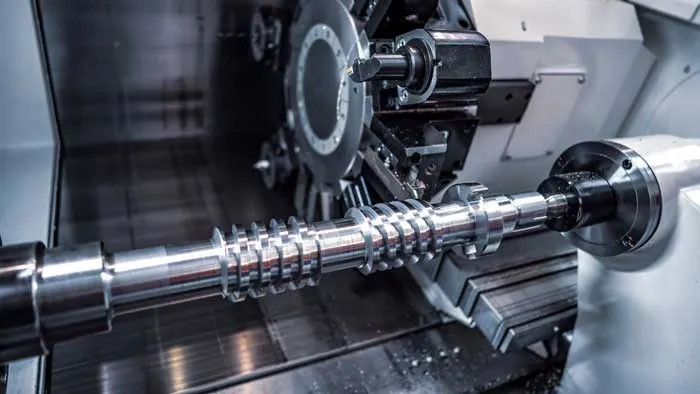

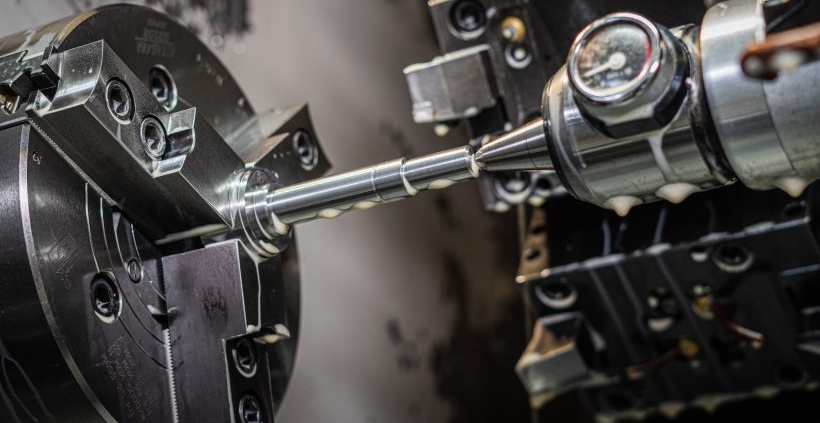

CNC (Computer Numerical Control) precision became additives are components manufactured using lathes which may be automatic and controlled with the aid of modern day laptop packages. These machines can produce tricky and actual components with tight tolerances, complex geometries, and first-rate surface finishes. CNC precision turning includes rotating a workpiece on the identical time as a slicing device is moved along a couple of axes to put off material and create the desired form.

What sets CNC precision grew to turn out to be additives aside isn’t always without a doubt their dimensional accuracy, but the consistency with which they may be replicated—even in excessive-volume manufacturing. This is critical for sectors like defense and healthcare, wherein difficulty failure can result in catastrophic outcomes.

The Demands of Defense Applications

In the protection area, tool must characteristic flawlessly in harsh environments. From plane and missile structures to superior communique gadgets and self sufficient structures, each product integrates numerous small however crucial precision-grew to grow to be elements. These additives need to meet rigorous necessities for typical performance, power, and durability.

Key Benefits in Defense:

- High Tolerance Precision: Military programs often require additives with tolerances as tight as ±0.001 mm. CNC precision turning gives you the desired accuracy to make sure that elements fit flawlessly and feature reliably under extreme situations.

- Material Versatility: CNC precision turning facilitates a big range of materials, including immoderate-strength alloys, stainless steel, titanium, and specialized protection-grade composites. These substances are vital for withstanding excessive pressures, temperatures, and corrosive environments.

- Consistency in Mass Production: Defense production often involves generating heaps of same components that ought to meet strict specs. CNC machines ensure regular output, lowering variability and the risk of failure.

- Complex Geometries: Many protection components, along with steerage device housings or weapon system connectors, require problematic designs. CNC precision turning makes it possible to manufacture those components with complex profiles and inner competencies.

- Reduced Lead Times: With virtual programming and automated device paths, CNC turning allows for fast manufacturing and faster prototyping—essential for assembly urgent safety deployment timelines.

CNC Precision Turned Components in Medical Applications

The clinical enterprise, similar to the protection sector, locations a top elegance on accuracy, cleanliness, and reliability. In gadgets along with surgical units, implants, diagnostic system, and prosthetics, CNC precision have become additives play a important function.

Key Benefits in Medical Applications:

- Micro-Scale Precision: Many clinical components are tremendously small—utilized in gadgets like pacemakers, insulin pumps, and surgical gear. CNC precision turning lets in for the advent of these miniature additives with impeccable detail and consistency.

- Biocompatible Materials: CNC machines can manner titanium, surgical-grade stainless steel, and PEEK, which might be commonly applied in scientific gadgets due to their biocompatibility and non-corrosive nature.

- Stringent Quality Assurance: Medical manufacturing adheres to strict regulatory requirements like ISO 13485 and FDA requirements. CNC precision turning offers traceability, repeatability, and high-quality manage had to comply with these guidelines.

- Surface Finish Quality: Medical components often require extraordinarily-clean surfaces to reduce friction and bacterial boom. CNC turning achieves fantastic floor finishes, minimizing the want for put up-processing.

- Customization for Patient-Specific Solutions: With the aid of CAD/CAM software, CNC precision turning lets in manufacturers to deliver custom implants or prosthetics tailor-made to individual sufferers, making sure better effects and luxury.

Meeting Industry Standards with CNC Precision Turning

Both protection and clinical industries require manufacturers to comply with plenty of stringent requirements. CNC precision became components meet those necessities via:

- AS9100 Certification for aerospace and protection

- ISO 13485 for clinical device production

- MIL-SPEC Compliance for navy specs

Statistical Process Control (SPC) for continuous terrific development

These requirements necessitate no longer truely outstanding engineering but robust documentation, cloth traceability, and a willpower to brilliant at every stage of the producing device.

Technological Advancements Supporting High-Precision Turning

The evolution of CNC precision turning has been fueled by means of the use of non-prevent innovation:

- Multi-Axis Machines: Swiss-fashion and multi-axis CNC lathes allow for greater complex element geometries with fewer setups and more tempo.

- Live Tooling: Enables milling, drilling, and tapping operations within the same setup, reducing cycle instances and growing accuracy.

- Automated Inspection Systems: Integrated vision structures and coordinate measuring machines (CMMs) ensure that additives meet tight tolerances at some stage in manufacturing.

- Smart Manufacturing Integration: Real-time tracking and facts analytics help enhance machine utilization, reduce downtime, and assist traceability.

These innovations make CNC precision turning greater versatile and adaptable to the evolving goals of the defense and clinical sectors.

Challenges and How They’re Addressed

While CNC precision grew to become additives provide numerous blessings, producers still face traumatic situations along side:

- Material Machinability: Some protection and clinical-grade substances are hard to gadget. Expertise in tooling and feed charges is essential to avoid put on and maintain tolerances.

- Complex Regulatory Environments: Staying compliant requires tremendous investment in exceptional manipulate structures and personnel training.

- Short Lead Times: Defense and clinical crises often call for speedy turnaround. Lean manufacturing practices and virtual workflows assist address this need.

- Leading CNC precision turning stores put money into R&D, education, and manner optimization to conquer the ones hurdles and maintain a competitive part.

Real-World Applications and Examples

- Defense: Precision grew to emerge as bushings, missile nostril cones, sensor housing gadgets, and radio frequency connectors are all synthetic via CNC turning.

- Medical: Bone screws, catheter recommendations, stent additives, and laparoscopic surgical tool shafts are common CNC precision have become additives.

- In each sectors, the smallest detail regularly has the most massive impact on tool functionality and safety.

Conclusion

CNC precision grew to become additives are crucial to the performance, protection, and innovation in protection and scientific applications. Whether it is equipping a soldier with superior weaponry or enabling a physician with dependable devices, precision is non-negotiable. The talents provided with the resource of CNC precision turning—accuracy, material versatility, scalability, and compliance—make it a foundational manufacturing approach for the maximum worrying industries.

As the need for excessive-universal overall performance, miniaturized, and complicated additives keeps to develop, the location of CNC precision turning will pleasant turn out to be greater vital. By investing in advanced CNC technologies and partnering with skilled manufacturers, stakeholders in protection and scientific industries can ensure that their products now not only meet the equal old—however define it.

Leave a Reply

Want to join the discussion?Feel free to contribute!