The Future of Sustainability: How Lithium Battery Recycling Machines Are Transforming the Industry

In today’s world, the growing demand for electric vehicles (EVs) and renewable energy systems has led to an unprecedented increase in the use of lithium-ion batteries. However, the rise in battery consumption has also brought about the challenge of managing battery waste. As these batteries reach the end of their life cycle, Lithium Battery Recycling Machines have emerged as a critical solution to address the growing concern of e-waste and promote a sustainable future.

In this guest post, we will explore how Lithium Battery Recycling Machines play a vital role in making the recycling process efficient, environmentally friendly, and economically viable.

Why Recycling Lithium Batteries Is Crucial

Lithium-ion batteries power everything from smartphones to electric vehicles (EVs). These batteries contain valuable materials such as lithium, cobalt, nickel, and graphite that can be reused, significantly reducing the need for mining and preventing further environmental damage. However, improper disposal of lithium batteries can cause severe environmental hazards, including soil and water contamination.

Lithium Battery Recycling Machines help recover these precious materials while ensuring that harmful elements are safely removed from the environment. By recycling lithium batteries, industries can reduce waste, conserve resources, and promote a circular economy.

The Role of Lithium Battery Recycling Machines

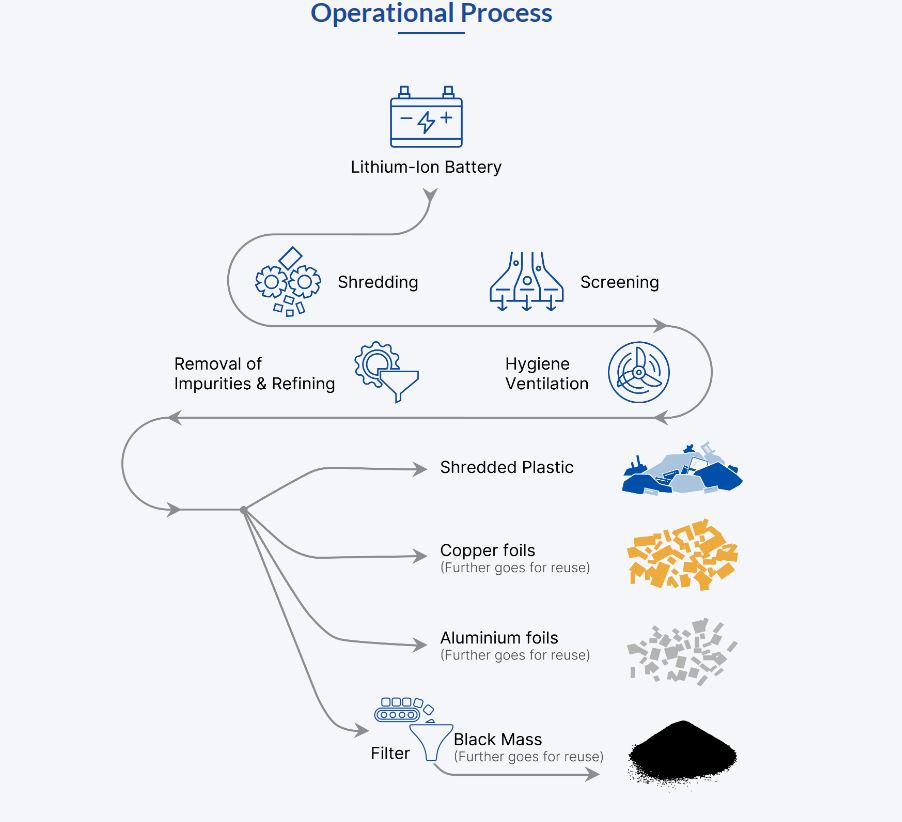

Lithium Battery Recycling Machines are designed to process used batteries and extract valuable materials for reuse. These machines are equipped with advanced technologies to handle the complex process of safely dismantling batteries, separating different materials, and extracting recyclable elements.

Key components of Lithium Battery Recycling Machines include:

1. Shredding and Crushing Systems

The first step in battery recycling involves breaking down the battery into smaller pieces. The shredding and crushing systems in Lithium Battery Recycling Machines efficiently break down the batteries while minimizing the risk of fire or explosion.

2. Separation Technology

Once the batteries are shredded, the next step involves separating the valuable materials. Magnetic separation, air classification, and other methods are used to separate metals like lithium, cobalt, nickel, and copper from plastics and other non-metallic components.

3. Chemical Processes

To recover the maximum amount of lithium and other materials, chemical processes such as hydrometallurgy and pyrometallurgy are used. These methods extract metals from the battery waste in a controlled and environmentally friendly manner.

4. Refining and Purification

After the materials are extracted, they undergo a refining and purification process to ensure that they meet industry standards. The result is high-quality, reusable metals that can be reintegrated into the production of new batteries.

Benefits of Lithium Battery Recycling Machines

1. Environmental Impact Reduction

By properly recycling lithium batteries, Lithium Battery Recycling Machines help prevent the release of toxic substances like cadmium and mercury into the environment. This reduces soil and water contamination and ensures that harmful waste is handled responsibly.

2. Resource Conservation

The primary advantage of recycling lithium batteries is the recovery of valuable materials. With Lithium Battery Recycling Machines, materials such as lithium, cobalt, nickel, and manganese are extracted and reused in the manufacturing of new batteries, reducing the need for mining and conserving natural resources.

3. Economic Value

Recycling lithium batteries can be economically beneficial. The recovered materials can be sold, offsetting the cost of the recycling process. Moreover, as the demand for EVs and renewable energy systems grows, so does the value of the materials used in these systems, making battery recycling an increasingly profitable industry.

4. Improved Energy Efficiency

The advanced technology used in Lithium Battery Recycling Machines ensures the process is highly efficient, using less energy compared to traditional recycling methods. This efficiency not only reduces the environmental footprint of the recycling process but also lowers operational costs for recycling companies.

Key Considerations When Choosing Lithium Battery Recycling Machines

When selecting Lithium Battery Recycling Machines, it’s crucial to consider factors that impact the efficiency and sustainability of the recycling process:

1. Technology and Innovation

Opt for machines equipped with the latest technological advancements to maximize the recovery of materials and minimize energy consumption. Machines with advanced separation and chemical recovery systems offer superior performance and higher recycling rates.

2. Safety Features

Battery recycling is a delicate process due to the flammable and potentially hazardous nature of lithium batteries. Ensure that the machines you choose come with safety features such as explosion-proof designs, fire suppression systems, and advanced monitoring systems.

3. Capacity and Throughput

Depending on the scale of your operation, consider the capacity of the Lithium Battery Recycling Machines. Choose machines that can handle the volume of batteries you intend to recycle while maintaining high processing efficiency.

4. Compliance with Regulations

Battery recycling is subject to environmental regulations and standards. Ensure that the machines comply with local and international standards for waste management, emissions, and worker safety.

The Future of Lithium Battery Recycling Machines

The global demand for Lithium Battery Recycling Machines is expected to rise significantly in the coming years as more industries focus on sustainability and waste reduction. With advancements in battery technology and increased adoption of electric vehicles, the recycling industry is poised to play an essential role in ensuring a sustainable future.

In the future, we can expect Lithium Battery Recycling Machines to become even more efficient, with improved recovery rates and lower environmental impact. Innovations in automation, artificial intelligence, and machine learning will further enhance the precision and speed of the recycling process, ensuring that valuable resources are recovered faster and more cost-effectively.

Conclusion

As the demand for lithium-ion batteries continues to rise, so does the need for efficient and environmentally responsible recycling methods. Lithium Battery Recycling Machines are at the forefront of this movement, enabling industries to recover valuable materials, reduce waste, and contribute to a circular economy.

If you’re looking for cutting-edge technology to help recycle lithium batteries efficiently and sustainably, consider partnering with Mettherm INC. Our Lithium Battery Recycling Machines are designed to meet the growing demands of today’s industries, ensuring that you can recycle batteries with maximum efficiency and minimal environmental impact.

Lithium Battery Recycling Machines

Lithium Battery Recycling Machines