CNC Milled Aluminum Parts Precision and Reliability in Modern Manufacturing

In today’s fast-paced manufacturing industry, CNC milled aluminum parts are in high demand due to their precision, strength, and lightweight properties. Aluminum is widely used across industries such as aerospace, automotive, electronics, and medical devices, and when combined with advanced CNC machining processes, it becomes a game-changer for high-performance applications. This article explores the benefits, applications, and technical considerations of CNC-milled aluminum, with a focus on how precision-driven solutions like aluminum extrusion fabrication and strict CNC machining tolerances ensure quality results.

Why CNC Milled Aluminum Parts are Essential

Aluminum is known for its durability, resistance to corrosion, and excellent machinability. When used in CNC milled aluminum parts, these properties are enhanced to meet strict industry standards. Unlike other materials, aluminum can be milled to extremely tight tolerances, making it a preferred choice for engineers and product developers who require accuracy and efficiency.

Key Benefits of CNC Milled Aluminum Parts

- Lightweight strength – Reduces overall component weight while maintaining structural integrity.

- Corrosion resistance – Ideal for outdoor and industrial environments.

- Cost-effectiveness – Faster production cycles and lower material costs compared to other metals.

- Design flexibility – Easy to customize into complex geometries without sacrificing precision.

By combining these benefits, CNC milled aluminum parts provide manufacturers with the perfect balance of reliability and performance.

The Role of CNC Machining in Aluminum Fabrication

CNC machining is a subtractive manufacturing process where material is removed from a solid block of aluminum to achieve the desired shape. The introduction of computer numerical control (CNC) ensures maximum accuracy during this process.

CNC Machining Tolerances: Why They Matter

One of the critical factors in creating CNC milled aluminum parts is the ability to maintain precise CNC machining tolerances. Tolerances define the allowable deviation from the specified dimensions, and achieving tighter tolerances is crucial for parts that must fit seamlessly into complex assemblies.

For industries like aerospace and medical devices, even minor deviations can cause failures. That’s why expert manufacturers pay close attention to CNC machining tolerances to ensure every part performs reliably.

Aluminum Extrusion Fabrication vs. CNC Milling

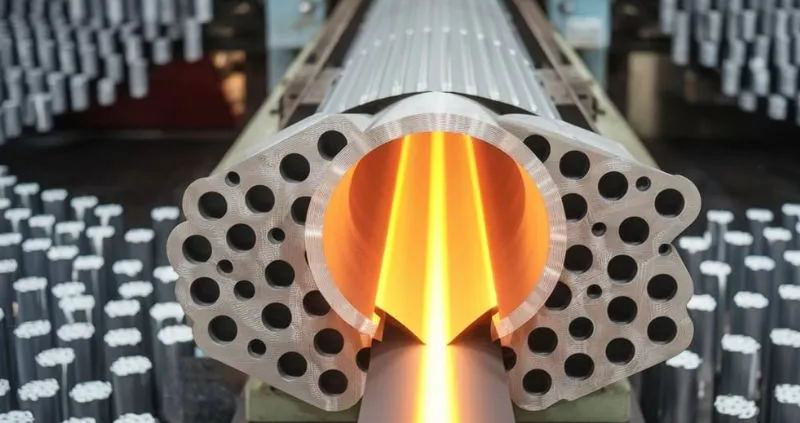

Both aluminum extrusion fabrication and CNC milling play essential roles in manufacturing aluminum components. While milling focuses on cutting away material, extrusion involves pushing heated aluminum through a die to create long, uniform profiles.

Advantages of Aluminum Extrusion Fabrication

- Efficient production of uniform shapes.

- Excellent for structural components like rails, frames, and enclosures.

- Lower cost for large-volume production runs.

Combining Extrusion with CNC Milling

Often, extruded aluminum profiles are further processed using CNC milling to add holes, slots, or other custom features. This hybrid approach allows manufacturers to optimize both cost and precision. For example, a company may produce structural frames through aluminum extrusion fabrication, then apply CNC milling to integrate detailed designs with strict CNC machining tolerances.

Applications of CNC Milled Aluminum Parts

The versatility of CNC milled aluminum parts makes them suitable for a wide range of industries.

Aerospace Industry

- Lightweight components reduce aircraft weight, improving fuel efficiency.

- Critical structural parts rely on tight CNC machining tolerances to ensure safety.

Automotive Sector

- Used in engine components, housings, and performance upgrades.

- Supports high-volume production with repeatable quality.

Electronics and Consumer Goods

- Aluminum provides excellent thermal conductivity, ideal for heat sinks and enclosures.

- Smooth surface finish enhances product aesthetics.

Medical Devices

- Surgical instruments and device housings benefit from aluminum’s non-toxic, corrosion-resistant nature.

- Precision milling ensures components meet strict industry regulations.

Challenges in Manufacturing CNC Milled Aluminum Parts

While CNC milled aluminum parts offer many benefits, there are challenges manufacturers must overcome to maintain quality.

Material Properties

Aluminum is softer than steel, which can sometimes lead to deformation during high-speed milling if not carefully managed.

Maintaining Tight CNC Machining Tolerances

Achieving and maintaining precise CNC machining tolerances requires high-quality equipment, advanced software, and skilled operators.

Balancing Cost and Quality

While aluminum is cost-effective, producing complex CNC milled aluminum parts with tight tolerances can increase production costs. Manufacturers often balance aluminum extrusion fabrication and milling techniques to optimize results.

Future Trends in CNC Milled Aluminum Parts

As industries continue to demand more precision and efficiency, the production of CNC milled aluminum parts is evolving with advanced technologies.

Automation and AI Integration

Smart CNC machines with AI-driven software help maintain consistent CNC machining tolerances and reduce human error.

Sustainable Manufacturing

Recycling aluminum and adopting energy-efficient machining practices are becoming priorities. Aluminum extrusion fabrication will play a major role in reducing waste.

Customization at Scale

With advanced CNC machining, manufacturers can deliver highly customized parts without compromising on speed or quality.

Choosing the Right Partner for CNC Milled Aluminum Parts

When selecting a manufacturer, businesses should look for expertise in both CNC milled aluminum parts and aluminum extrusion fabrication, backed by proven success in maintaining tight CNC machining tolerances. The right partner should provide:

- Advanced CNC equipment.

- Experienced engineers.

- Consistent quality control.

- Scalable production capacity.

For companies across industries, partnering with sheet metal and CNC machining experts ensures they receive reliable parts that meet or exceed expectations.

Conclusion

The demand for CNC milled aluminum parts continues to grow as industries prioritize precision, durability, and efficiency. With the right combination of aluminum extrusion fabrication and strict adherence to CNC machining tolerances, manufacturers can deliver solutions that support innovation and long-term reliability. Whether for aerospace, automotive, electronics, or medical applications, CNC milling ensures aluminum components remain at the forefront of modern manufacturing.

By embracing advanced CNC technologies and precision-driven processes, businesses can stay competitive while ensuring their products meet the highest standards of performance and quality.

Leave a Reply

Want to join the discussion?Feel free to contribute!