Different Types of Steam Boilers & Their Applications

Steam boilers play a crucial role in industrial operations, providing the thermal strength required for a wide variety of strategies—from heating and sterilization to electricity technology and chemical reactions. Depending on the size, motive, and working conditions of a facility, distinct forms of steam boilers are used to satisfy unique desires.

Understanding the diverse types of steam boilers and their applications is essential for plant managers, engineers, and facility operators trying to optimize electricity use, lessen prices, and make sure operational safety. This manual explores the maximum commonplace steam boiler types and discusses their realistic makes use of across diverse industries.

Why Steam Boilers Are Essential

Steam boilers convert water into steam via the application of heat, frequently produced by using burning fuels such as herbal gasoline, oil, biomass, or the use of energy. The generated steam is then distributed for:

- Industrial heating

- Power generation

- Mechanical drive (e.G., turbines)

- Sterilization and sanitation

- Chemical processing

- Food and beverage manufacturing

Since unique industries have varied requirements in terms of stress, temperature, gasoline kind, and operational flexibility, selecting the right boiler design is important for performance, protection, and regulatory compliance.

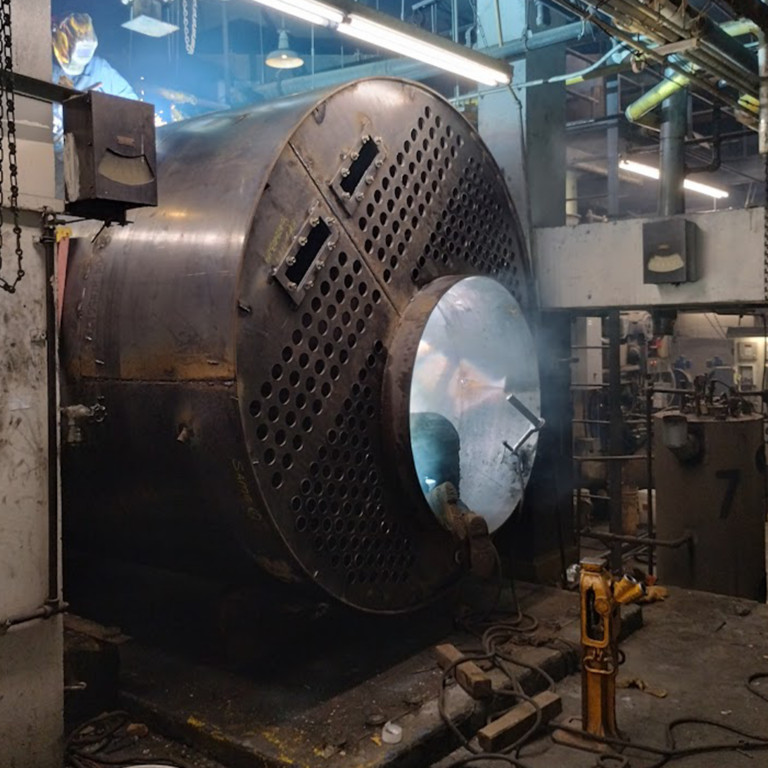

1. Fire-Tube Boilers

Description:

Fire-tube boilers are one of the most conventional and broadly used designs. In this configuration, hot gases from the combustion method skip via tubes surrounded by using water. The heat is transferred via the tube walls, converting the encircling water into steam.

Key Features:

- Simple design

- Cost-powerful

- Easy to operate and maintain

- Low to medium stress operations

Common Applications:

- Heating structures for buildings and institutions

- Food processing flora

- Breweries

- Small manufacturing centers

Limitations:

- Slower steam production

- Not ideal for excessive-stress packages

2. Water-Tube Boilers

Description:

Water-tube boilers paintings opposite to fireplace-tube designs. Water circulates internal tubes, which can be heated externally with the aid of warm gases from combustion. This layout lets in for higher strain and temperature abilities.

Key Features:

- High steam technology fees

- Operates at excessive pressure and temperature

- Compact layout for huge output

Common Applications:

- Power flowers

- Petrochemical refineries

- Chemical production

- Industrial steam technology

Limitations:

- More complex

- Higher set up and upkeep costs

3. Electric Steam Boilers

Description:

Electric steam boilers use strength to warmth water and generate steam without using combustion. They are compact, smooth, and quiet, making them suitable for specialised environments.

Key Features:

- Zero emissions

- High efficiency

- Precise temperature manipulate

- Compact footprint

Common Applications:

- Laboratories and clean rooms

- Hospitals and healthcare

- Food and beverage sterilization

- Pharmaceutical production

Limitations:

- High working charges in regions with high-priced strength

- Limited capability as compared to fuel-fired systems

4. Coil-Type Boilers (Rapid Steam Generators)

Description:

Coil-type or as soon as-through boilers feature a spiral coil that water passes thru and is instantly turned into steam. These devices heat up and respond quick, often requiring much less area.

Key Features:

- Fast begin-up time

- Small and lightweight

- Minimal water content, decreasing explosion chance

Common Applications:

- Food and beverage

- Instantaneous steam technology for cleaning

- Packaging flora

Limitations:

- Not perfect for non-stop high-load programs

- Requires terrific feedwater

5. Modular Boilers

Description:

Modular boilers include a couple of smaller units that paintings together to meet steam demands. They can be grew to become on or off as needed, providing flexibility and performance.

Key Features:

- Scalable steam manufacturing

- Easy to keep

- Redundancy reduces downtime

- Ideal for fluctuating masses

Common Applications:

- Institutions (schools, hospitals)

- Manufacturing with variable steam wishes

- District heating

Limitations:

- Higher in advance price because of a couple of gadgets

- Requires appropriate machine design for top-rated overall performance

6. Waste Heat Recovery Boilers (WHRB)

Description:

WHRBs make use of the heat from commercial exhaust gases or approaches (consisting of gasoline mills or engines) to generate steam, lowering electricity waste and improving overall efficiency.

Key Features:

- Energy-saving solution

- Reduces carbon footprint

- Can be integrated with different systems

Common Applications:

- Cement flowers

- Refineries

- Gas turbine operations

- Chemical production

Limitations:

- Depends at the availability and temperature of waste heat

- Higher complexity in system integration

7. Fluidized Bed Combustion (FBC) Boilers

Description:

FBC boilers use a bed of solid debris (like sand or ash) suspended through upward-flowing air to burn fuel efficaciously at lower temperatures. This method allows for higher gas flexibility and reduced emissions.

Key Features:

- Burns low-grade fuels successfully

- Lower NOx and SOx emissions

- High combustion performance

Common Applications:

- Power technology

- Pulp and paper generators

- Agro-waste primarily based industries

Limitations:

- More complicated device

- Requires skilled operation and upkeep

8. Industrial Package Boilers

Description:

These are pre-engineered and assembled boiler structures delivered as a complete bundle. They are compact, efficient, and designed for short set up.

Key Features:

- Easy and fast setup

- Factory-tested for performance

- Space-saving layout

Common Applications:

- Textile generators

- Pharmaceuticals

- Small to medium industries

- Institutions

Limitations:

- Limited customization

- May now not meet complex or fairly specialised necessities

Selecting the Right Boiler for Your Application

Choosing the ideal steam boiler depends on several key factors:

- Steam Demand

Understand your top and average steam load to decide boiler capacity. - Operating Pressure

Certain procedures require high-strain steam, at the same time as others can function at low pressures. - Fuel Availability

Choose a gasoline type that is fee-powerful and with ease to be had for your location (natural gas, oil, biomass, strength, and so forth.). - Space Constraints

Ensure the chosen boiler fits your plant format and allows room for preservation get admission to. - Efficiency & Sustainability

Look for modern-day, strength-efficient designs that assist emission reduction dreams. - Cost of Ownership

Evaluate no longer simply the upfront fee, however also gasoline costs, renovation, downtime, and lifespan.

Industry-Specific Boiler Applications

| Industry | Typical Boiler Type | Application |

| Food & Beverage | Fire-tube, Electric, Modular | Cooking, sterilization, pasteurization |

| Chemical & Petrochemical | Water-tube, WHRB, FBC | Reaction manage, distillation, electricity technology |

| Textile | Fire-tube, Package | Dyeing, drying, ironing |

| Power Generation | Water-tube, FBC | Turbine steam, cogeneration |

| Pharmaceuticals | Electric, Modular, Package | Sterile steam, components methods |

| Hospitals | Electric, Modular | Sterilization, laundry, heating |

Supreme Boilers: Engineered Excellence for Every Industrial Need

When it involves overall performance, reliability, and innovation in steam era, Supreme Boilers is a name industries consider. With a complete variety of high-efficiency boilers engineered to fulfill the demands of numerous programs, Supreme offers tailor-made solutions for sectors ranging from meals processing to heavy production.

Their FPS Series and FST Series deliver amazing gasoline efficiency and strong performance for popular commercial desires, at the same time as the ESP Series offers smooth and compact electric steam solutions for touchy environments. For precision programs, the PLW Series ensures constant steam with low water content material, and the heavy-duty SM4 Series and SM5 Series are built for excessive-potential, demanding operations.

Whether you are upgrading your gadget or constructing from the ground up, Supreme Boilers combines best production with expert aid to help you achieve operational excellence.

Final Thoughts

The diversity of steam boiler sorts lets in industries to tailor their energy systems to particular needs, whether or not it’s precision, efficiency, speedy steam technology, or sustainability. Understanding the strengths and boundaries of every boiler type is crucial in making the right selection.

Whether you’re installing a brand new system or upgrading an present one, usually recall no longer just the operational necessities however additionally the lengthy-term performance, protection, and environmental effect.

Leave a Reply

Want to join the discussion?Feel free to contribute!