How to Choose the Right Tear Strip for Your Needs?

Tear strips have become essential components in modern packaging, providing convenience, security, and functionality across multiple industries. Whether you’re in pharmaceuticals, food packaging, or consumer electronics, choosing the right tear strip can significantly improve the user experience and protect the product. In this article, we’ll explore how to choose the ideal tear strip and why it matters for your business.

What is a Tear Strip?

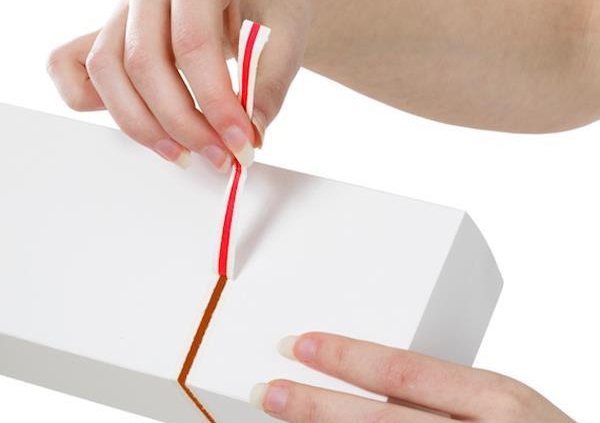

A tear strip is a thin, reinforced line or ribbon embedded in packaging materials, designed to allow users to open the package easily without needing tools. It is commonly found in strip packs, cartons, envelopes, shrink wraps, and blister packaging. Tear strips not only simplify unboxing but also enhance tamper-evidence and product safety.

1. Consider the Packaging Material

Different packaging materials require different tear strip designs. For instance, paperboard cartons use paper or plastic tear strips. On the other hand, foil-based strip packs or laminated films need high-strength tear strips.

If you’re working with rigid plastic or shrink wrap, go for a tear strip with higher tensile strength. It should cut cleanly through the material without compromising the packaging integrity. For eco-friendly packaging, choose recyclable or biodegradable tear strips to stay sustainable.

2. Understand the Functionality You Need

The purpose of your tear strip affects your choice. Are you offering strip packs that need to be opened daily, like medications? Or are you packaging electronics or luxury goods that require tamper-proofing?

Here are some functional requirements to consider:

- Easy-open: For food and household items.

- Tamper-evident: For pharmaceuticals, supplements, and cosmetics.

- Reusable: For resealable strip packs or pouches.

- Child-resistant: Important for dangerous or restricted items.

Select a tear strip that aligns with your packaging’s purpose. The right type will balance accessibility with security.

3. Focus on User Experience

In today’s market, consumer convenience can be a key differentiator. A well-designed tear strip adds value to your product. Customers want packaging they can open quickly and cleanly—without knives or scissors.

If the tear strip is too hard to use, you risk frustrating the user. That can lead to poor reviews or reduced customer satisfaction. Make sure your tear strip pulls smoothly and works reliably. If possible, test different designs on your actual product packaging before scaling.

4. Choose the Right Adhesive or Lamination

The adhesive used in applying the tear strip is just as important as the strip itself. If the bond is too weak, the strip may detach or fail. Too strong, and it may tear the package in the wrong place.

Many strip packs use heat-sealed lamination to secure the tear strip within multiple packaging layers. This ensures a smooth tear while maintaining package integrity. You should consult with your packaging supplier or engineer to select the best adhesive for your product type.

5. Customization and Branding Options

A tear strip can also become part of your brand identity. Custom colors, logos, and even printed instructions can be included on the strip. This adds a touch of sophistication and increases brand recall.

For example, adding your logo or a safety warning directly on the tear strip helps customers identify genuine products. It’s also a subtle but powerful way to enhance your brand’s visibility during the unboxing process.

6. Compliance with Industry Standards

Some products—especially pharmaceuticals and food—must comply with strict regulatory requirements. Packaging, including the tear strip, must follow these standards for safety, hygiene, and quality.

In strip pack packaging used for tablets or powders, the tear strip must not compromise the seal. The strip should only open when intended, maintaining the product’s sterility and shelf life.

Check your industry guidelines before choosing a tear strip. Ensure your supplier is familiar with compliance requirements and has certifications such as ISO or FDA approval if applicable.

7. Evaluate Cost and Manufacturing Compatibility

While functionality is important, cost-effectiveness also plays a role. Custom tear strips, especially those with printed branding or special materials, may be more expensive. Consider your production volume, target price point, and whether the cost adds enough value to justify the investment.

Also, check that your manufacturing equipment can handle the integration of the tear strip. Some packaging machines require specific configurations or upgrades to work with tear strips, especially for strip pack formats.

Work closely with your supplier to ensure seamless integration into your existing production lines.

Common Types of Tear Strips

To choose the right one, it helps to know the different tear strip types:

- Plastic tear tape: Common for shrink wraps and cartons; strong and colorful.

- Metallic tear strip: Offers high strength, often used for tamper-proof applications.

- Paper tear tape: Eco-friendly and recyclable, used in sustainable packaging.

- Heat-sealed tear strip: Used in strip packs, providing strong seals and clean tearing.

Each type has pros and cons based on packaging needs and user expectations.

Why Tear Strips Matter in Strip Packs

In strip pack packaging, tear strips are essential. They help consumers access single doses of medicine or supplements with ease. A poorly designed strip can lead to contamination, dosage errors, or packaging failure.

Choosing a durable, easy-to-use tear strip enhances safety, reduces product loss, and ensures customer satisfaction. It’s a critical detail in pharmaceutical and health product packaging.

Final Thoughts

Selecting the right tear strip isn’t just about packaging—it’s about enhancing functionality, safety, and brand perception. From strip pack applications to tamper-evident boxes, the right tear strip can make a lasting difference.

Consider the packaging material, customer experience, cost, compliance, and customization when choosing your tear strip. Working with experienced suppliers and testing designs thoroughly will help you find the best solution for your specific needs.

Make your packaging smarter—choose the right tear strip today.

Leave a Reply

Want to join the discussion?Feel free to contribute!