Designing a Planetary Gearbox: Principles, Process, and Best Practices

Planetary gearboxes are widely recognized for their compact design, high efficiency, and ability to deliver significant torque in a small footprint. They are used in diverse applications ranging from industrial automation to aerospace engineering. Designing a planetary gearbox requires a deep understanding of mechanical principles, precision engineering, and performance optimization to meet the specific needs of an application.

In this post, we’ll explore the fundamentals of planetary gearbox design, the key engineering considerations, and the step-by-step process to create a gearbox that delivers both performance and durability.

What is a Planetary Gearbox?

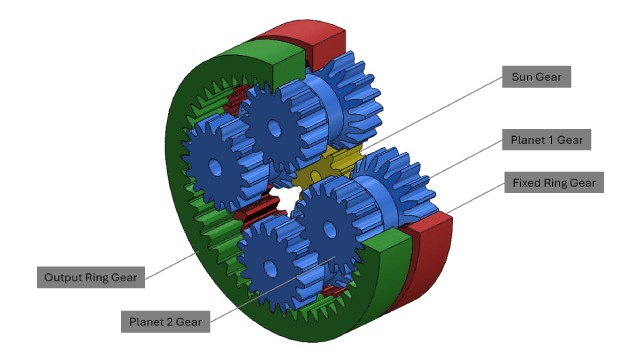

A planetary gearbox—also known as an epicyclic gearbox—consists of three main elements:

- Sun Gear: The central gear that transmits motion to the surrounding gears.

- Planet Gears: Multiple gears that revolve around the sun gear, held in place by a carrier.

- Ring Gear: An outer gear with internal teeth that meshes with the planet gears.

The configuration enables multiple gear contacts at once, allowing for high torque transmission and compact size, making it ideal for applications where space is limited but performance demands are high.

Core Design Considerations

When designing a planetary gearbox, engineers must account for multiple factors to ensure optimal performance and lifespan:

1. Torque and Load Requirements

Determining the maximum and continuous torque capacity is the first step. The number of planet gears and their diameter directly impact load distribution, ensuring that torque is shared across multiple contact points.

2. Gear Ratio

The gear ratio determines output speed and torque characteristics. Selecting the right combination of sun, planet, and ring gear teeth counts is crucial for matching application needs.

3. Efficiency

Frictional losses should be minimized through precision machining, proper lubrication, and optimized gear tooth profiles.

4. Material Selection

High-strength alloys, carburized steel, and advanced composites are often used to enhance durability while keeping weight low. Heat treatment improves wear resistance.

5. Lubrication and Cooling

Oil or grease lubrication reduces wear, improves efficiency, and prevents overheating. In high-speed or high-load applications, integrated cooling systems may be necessary.

6. Noise and Vibration Control

Optimizing gear profiles and ensuring precise alignment reduces noise and vibration, which is critical in robotics, automotive, and aerospace applications.

Step-by-Step Process of Designing a Planetary Gearbox

Step 1: Define Application Requirements

Before any CAD modeling or calculations, the application’s specific requirements must be outlined:

- Load capacity (Nm)

- Desired gear ratio

- Input and output speeds

- Environmental factors (temperature, moisture, dust)

- Weight and size constraints

Step 2: Gear Geometry and Ratio Calculations

Using standard gear ratio formulas, engineers determine the number of teeth for each gear component. The choice between single-stage, two-stage, or multi-stage planetary configurations depends on the required torque and reduction ratio.

Formula Example:

Gear Ratio = 1 + (Ring Gear Teeth / Sun Gear Teeth)

Step 3: Material Selection and Heat Treatment

Choosing the right material is crucial for strength and wear resistance. Surface hardening methods such as carburizing or nitriding extend operational life.

Step 4: Bearing and Shaft Design

Bearings must handle both radial and axial loads efficiently. Shafts require proper dimensioning to avoid deflection under load.

Step 5: Lubrication Strategy

Engineers must determine whether grease or oil lubrication is more suitable. Oil baths and circulation systems are common in heavy-duty applications.

Step 6: Housing and Sealing

The gearbox casing must provide rigidity and protect internal components from contamination. Seals prevent lubricant leakage and ingress of dirt or moisture.

Step 7: Prototyping and Simulation

Modern CAD software and finite element analysis (FEA) tools allow virtual testing before manufacturing. Simulations help identify potential issues such as gear tooth stress concentration or heat buildup.

Step 8: Manufacturing and Assembly

Precision manufacturing ensures gear tooth accuracy and alignment. Assembly tolerances must be maintained to avoid performance losses.

Step 9: Testing and Validation

The gearbox undergoes torque, speed, noise, and durability testing. Any performance deviation leads to refinement in design.

Common Challenges in Planetary Gearbox Design

- Heat Buildup – Excessive heat can degrade lubrication and damage components.

- Gear Tooth Wear – Poor material choice or lubrication can accelerate wear.

- Noise Issues – Misalignment or incorrect gear profile can cause unwanted noise.

- Space Constraints – Achieving high torque within a small size demands precision engineering.

Best Practices for Optimal Gearbox Design

- Use High-Quality Gear Profiles: Involute profiles with optimized pressure angles reduce losses.

- Implement Advanced Coatings: DLC (Diamond-Like Carbon) coatings reduce friction and wear.

- Regular Maintenance Planning: Designing with maintenance accessibility ensures longer life cycles.

- Integrate Sensors: Condition monitoring sensors for temperature, vibration, and oil quality can prevent unexpected failures.

Applications of Planetary Gearboxes

- Automotive: Automatic transmissions, hybrid vehicle drivetrains.

- Industrial Automation: Robotic arms, conveyor drives.

- Aerospace: Actuation systems, UAV propulsion.

- Renewable Energy: Wind turbine gear systems.

- Medical Equipment: Precision surgical tools and imaging devices.

Conclusion

Designing a planetary gearbox requires a combination of theoretical knowledge, practical experience, and advanced engineering tools. By carefully balancing torque requirements, efficiency, material selection, and durability, engineers can create gear systems that deliver high performance in compact, reliable packages. As industries demand more compact and energy-efficient machinery, the role of planetary gearbox design will only grow in importance.

Leave a Reply

Want to join the discussion?Feel free to contribute!